Back in 2014, Stantec Engineering Ltd was hired by the Town of Whitecourt to complete a preliminary study concerning the Wastewater Treatment Plant. The topic of smell has been a long-standing issue for downtown residents and those who frequent facilities near the plant such as Graham Acres. The Wastewater Treatment Plant Master Plan Study was completed by Stantec Engineering in 2016 and provided both short-term and long-term system improvements. The study also showed the best approach for future operations.

One of the big reasons for strong odours is the excessive sludge that is being created in part by large amounts of grit and materials in the wastewater stream. These materials impact the storage lagoons, aeration basins, digester tanks and clarifiers. A grit sampling study found that a high percentage of materials, less than 75 microns in size, were not being caught by conventional grit removal technologies. These non-biodegradable particulates were wreaking havoc, including wear and tear on the grinder pumps, and clogging up the sewer system.

Administration worked alongside Stantec to look at how to prevent the issue at the source. They came up with a five-point plan to tackle wastewater issues before they even reach the plant. Doing so could reduce the particulate in the system by as high as 40 percent. One of the steps involved education for business owners on how they care for wastewater equipment such as grease traps or wash bay sump pits. The plan also included providing an incentive program to encourage businesses to take part and penalties for those who do not. Council passed a new utility bylaw last fall, which gave Administration more power to do inspections and make sure Whitecourt businesses follow proper protocols when dealing with grit chambers.

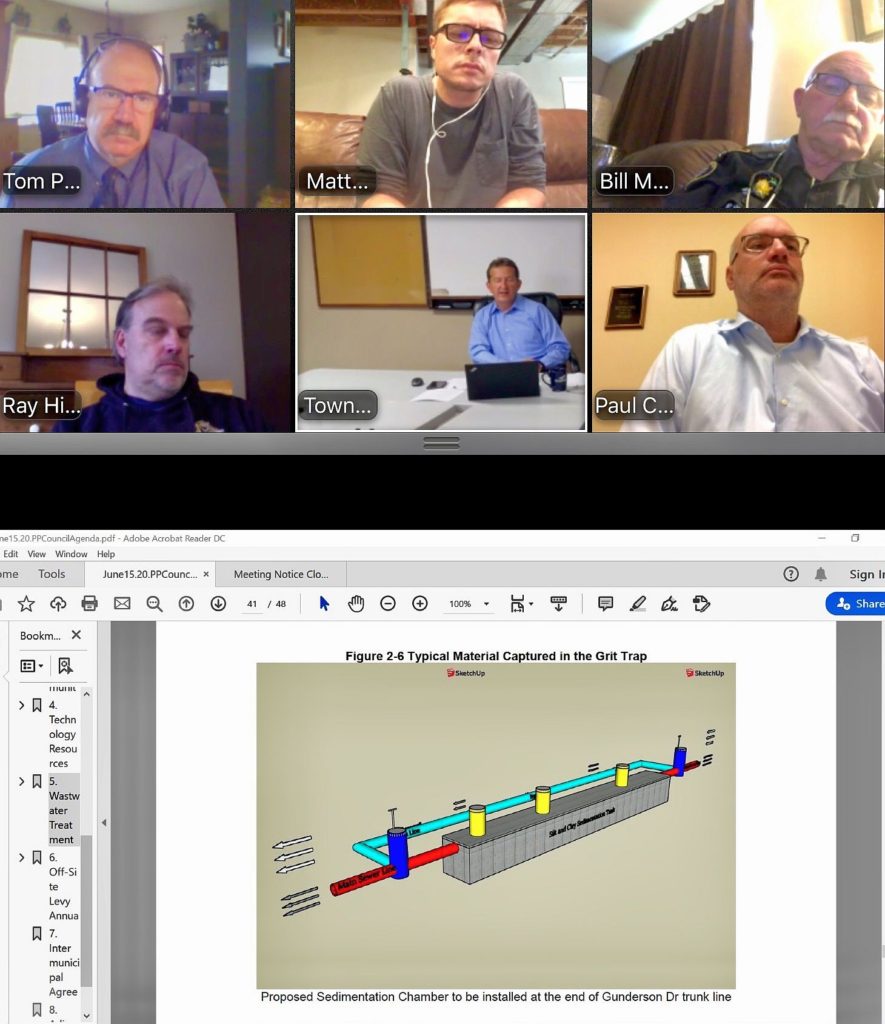

Trunk lines transport wastewater from the community and deposit it at the Water Treatment Plant. Currently, there are three trunk lines in the municipality. “One starts over by the water treatment plant, that runs through 49th, down 55th, and Dahl drive. The other one starts on 47th street and runs through Harold’s Hallow and parallel along Flats Road,” explained Nick Slootweg, Manager of Utilities, during the June 15 Policies and Priorities Committee Meeting. “We’ve taken samples out of all three of those trunk lines, and we clean them on a five-year rotation, but those two trunk lines that run through downtown and Flats Road have nowhere near the gritty material. It is basically just organics. There is a huge difference compared to the one coming from the industrial area, at Gunderson Drive.”

In fact, the trunk line at Gunderson needed cleaning because it was grit-filled. “We are talking large diameter pipes that were 70 percent filled with grit. Of course, that is over a 10 or 15 year period,” explained Town of Whitecourt CAO Peter Smyl. He said that getting rid of the grit is the best option for the community, especially in terms of cost, maintenance, and odour. “If we do our part, and businesses take part, we could get a lot of that grit out. If it does not enter the system, then it does not enter the sludge ponds, and the sludge ponds are the source of the odour. We have municipalities in Alberta that have a pond, and it looks just like a pond. It is not filled with 70 to 90 percent non-organic material, which is the grit,” said Smyl.

Councillor Matt Connell, who lives near the Water Treatment Plant, said that he is glad that they are once again looking into the issue. “The worst thing we could do is spent eight to twelve million dollars on something that isn’t necessarily going to solve the problem. I have recognized over the years that sometimes the quickest solution is not going to be the best solution. If you were going to bury an issue, you don’t bring it up every year and have discussions on solutions and making things better.”

So, what does this mean for residents? Slootweg explained that they would be acting on a couple of new plans in hopes that they help mitigate smells wafting off the ponds. “We are putting a freshwater cap on the pond each night, and we are working with snowmaking equipment to run a mist on the pond.” He said that they are in the process of borrowing a transformer to increase their voltage capabilities so they can run the large equipment and look to be up and running by the time this paper hits newsstands.

One of the ponds was recently emptied and will remain empty until necessary. “It’s easier to keep one going than two at the same time. This way, we will know which one is causing the problem,” he said. As for complaints, Slootweg asks residents to share their concerns and to be specific. He said that knowing there is an issue is best because then they can tweak their processes and approach it differently. “We can change our strategy based on when we get complaints. Adding more water more frequently or focusing on the evenings and maybe setting timers. That’s why we need to know.”

Ultimately, the odour issues come down to grit. “It is difficult to break down the organics in the pond when there’s so much grit within the sludge. The bacteria are trying to find their way around to break down the organics, so the grit makes a difference. Our grit is about 70 percent, whereas other communities are about 30 percent. That makes a big difference for breaking it down.” The Policies and Priorities Committee voted unanimously to have Administration proceed with looking into other odour mitigation ideas and capacity building options for the plant, which will be reviewed by Council this fall.

More Stories

Is your fire pit permit older than 2025? Then you need to get a new one

Kenyan delegation may visit Woodlands County this June

Let your voice be heard – Budget Open House happening early next month